Pneumatic Cylinder Jerking Problem . at royal cylinders, our engineers provide troubleshooting support and solutions to industrial cylinder leakage, jerking, creeping, bouncing, chattering,. prevent pneumatic cylinder failure by maintaining and repairing it regularly. When pressure is applied laterally to the axis it can cause a number of problems. the 4 conditions that can cause the pneumatic cylinder to fail are: Avoid mounting with side loads on the stem, because the cylinders are specifically designed to go “back and forth” as efficiently as possible and not to act as guides. Our guide to pneumatic cylinder maintenance covers. if your pneumatic cylinder is failing, the most likely culprit is side loading. Ideally there should be zero lateral loads on the cylinder.

from www.chegg.com

Ideally there should be zero lateral loads on the cylinder. the 4 conditions that can cause the pneumatic cylinder to fail are: prevent pneumatic cylinder failure by maintaining and repairing it regularly. at royal cylinders, our engineers provide troubleshooting support and solutions to industrial cylinder leakage, jerking, creeping, bouncing, chattering,. Avoid mounting with side loads on the stem, because the cylinders are specifically designed to go “back and forth” as efficiently as possible and not to act as guides. if your pneumatic cylinder is failing, the most likely culprit is side loading. When pressure is applied laterally to the axis it can cause a number of problems. Our guide to pneumatic cylinder maintenance covers.

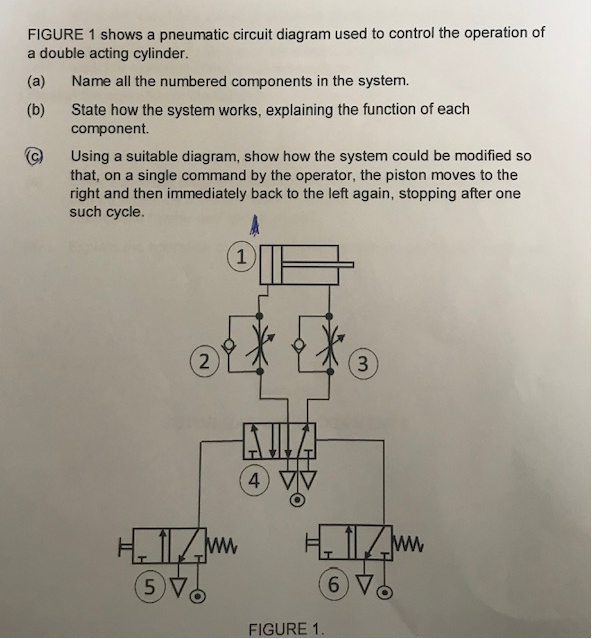

Solved FIGURE 1 shows a pneumatic circuit diagram used to

Pneumatic Cylinder Jerking Problem Avoid mounting with side loads on the stem, because the cylinders are specifically designed to go “back and forth” as efficiently as possible and not to act as guides. if your pneumatic cylinder is failing, the most likely culprit is side loading. Avoid mounting with side loads on the stem, because the cylinders are specifically designed to go “back and forth” as efficiently as possible and not to act as guides. When pressure is applied laterally to the axis it can cause a number of problems. prevent pneumatic cylinder failure by maintaining and repairing it regularly. the 4 conditions that can cause the pneumatic cylinder to fail are: Our guide to pneumatic cylinder maintenance covers. Ideally there should be zero lateral loads on the cylinder. at royal cylinders, our engineers provide troubleshooting support and solutions to industrial cylinder leakage, jerking, creeping, bouncing, chattering,.

From www.youtube.com

Pneumatic Cylinder Operation with Limit Switch । Hard wiring, PLC Pneumatic Cylinder Jerking Problem Our guide to pneumatic cylinder maintenance covers. the 4 conditions that can cause the pneumatic cylinder to fail are: prevent pneumatic cylinder failure by maintaining and repairing it regularly. if your pneumatic cylinder is failing, the most likely culprit is side loading. Ideally there should be zero lateral loads on the cylinder. Avoid mounting with side loads. Pneumatic Cylinder Jerking Problem.

From topafluid.com

Understanding Hydraulic Cylinder Jerking Problems Topa Pneumatic Cylinder Jerking Problem Avoid mounting with side loads on the stem, because the cylinders are specifically designed to go “back and forth” as efficiently as possible and not to act as guides. if your pneumatic cylinder is failing, the most likely culprit is side loading. at royal cylinders, our engineers provide troubleshooting support and solutions to industrial cylinder leakage, jerking, creeping,. Pneumatic Cylinder Jerking Problem.

From www.youtube.com

What is a pneumatic cylinder? YouTube Pneumatic Cylinder Jerking Problem if your pneumatic cylinder is failing, the most likely culprit is side loading. the 4 conditions that can cause the pneumatic cylinder to fail are: prevent pneumatic cylinder failure by maintaining and repairing it regularly. Avoid mounting with side loads on the stem, because the cylinders are specifically designed to go “back and forth” as efficiently as. Pneumatic Cylinder Jerking Problem.

From www.youtube.com

PNEUMATIC CYLINDER WORKINGAUTOMATION STUDIO SIMULATION YouTube Pneumatic Cylinder Jerking Problem Ideally there should be zero lateral loads on the cylinder. at royal cylinders, our engineers provide troubleshooting support and solutions to industrial cylinder leakage, jerking, creeping, bouncing, chattering,. Avoid mounting with side loads on the stem, because the cylinders are specifically designed to go “back and forth” as efficiently as possible and not to act as guides. Our guide. Pneumatic Cylinder Jerking Problem.

From www.youtube.com

Pneumatic Cylinder Seal Changing How to use a pneumatic cylinder Pneumatic Cylinder Jerking Problem When pressure is applied laterally to the axis it can cause a number of problems. the 4 conditions that can cause the pneumatic cylinder to fail are: at royal cylinders, our engineers provide troubleshooting support and solutions to industrial cylinder leakage, jerking, creeping, bouncing, chattering,. prevent pneumatic cylinder failure by maintaining and repairing it regularly. Avoid mounting. Pneumatic Cylinder Jerking Problem.

From farmergrows.com

Hydraulic Cylinder Jerking Problem 3 Solutions Farmer Grows Pneumatic Cylinder Jerking Problem at royal cylinders, our engineers provide troubleshooting support and solutions to industrial cylinder leakage, jerking, creeping, bouncing, chattering,. Avoid mounting with side loads on the stem, because the cylinders are specifically designed to go “back and forth” as efficiently as possible and not to act as guides. Ideally there should be zero lateral loads on the cylinder. When pressure. Pneumatic Cylinder Jerking Problem.

From instrumentationtools.com

HMI and PLC Programming for Pneumatic Cylinders and Actuators Pneumatic Cylinder Jerking Problem the 4 conditions that can cause the pneumatic cylinder to fail are: Ideally there should be zero lateral loads on the cylinder. When pressure is applied laterally to the axis it can cause a number of problems. Avoid mounting with side loads on the stem, because the cylinders are specifically designed to go “back and forth” as efficiently as. Pneumatic Cylinder Jerking Problem.

From www.e-pneumatic.com

How Pneumatic Cylinder Work? Described Instructions Pneumatic Blog Pneumatic Cylinder Jerking Problem prevent pneumatic cylinder failure by maintaining and repairing it regularly. at royal cylinders, our engineers provide troubleshooting support and solutions to industrial cylinder leakage, jerking, creeping, bouncing, chattering,. When pressure is applied laterally to the axis it can cause a number of problems. the 4 conditions that can cause the pneumatic cylinder to fail are: Ideally there. Pneumatic Cylinder Jerking Problem.

From www.powermotiontech.com

A Checklist for Matching Pneumatic Cylinders to Load Requirements Pneumatic Cylinder Jerking Problem Ideally there should be zero lateral loads on the cylinder. Our guide to pneumatic cylinder maintenance covers. Avoid mounting with side loads on the stem, because the cylinders are specifically designed to go “back and forth” as efficiently as possible and not to act as guides. at royal cylinders, our engineers provide troubleshooting support and solutions to industrial cylinder. Pneumatic Cylinder Jerking Problem.

From www.youtube.com

PNEUMATIC CYLINDERS PROBLEMS AND TROUBLESHOOTING IN தமிழ் YouTube Pneumatic Cylinder Jerking Problem Ideally there should be zero lateral loads on the cylinder. Avoid mounting with side loads on the stem, because the cylinders are specifically designed to go “back and forth” as efficiently as possible and not to act as guides. prevent pneumatic cylinder failure by maintaining and repairing it regularly. at royal cylinders, our engineers provide troubleshooting support and. Pneumatic Cylinder Jerking Problem.

From hakpneumatic.com

5 Tips to Troubleshoot Pneumatic Systems HAK Pneumatic Cylinder Jerking Problem When pressure is applied laterally to the axis it can cause a number of problems. if your pneumatic cylinder is failing, the most likely culprit is side loading. the 4 conditions that can cause the pneumatic cylinder to fail are: Our guide to pneumatic cylinder maintenance covers. at royal cylinders, our engineers provide troubleshooting support and solutions. Pneumatic Cylinder Jerking Problem.

From www.quadfluiddynamics.com

5 Signs Your Hydraulic Cylinder Has a Problem Pneumatic Cylinder Jerking Problem if your pneumatic cylinder is failing, the most likely culprit is side loading. Ideally there should be zero lateral loads on the cylinder. When pressure is applied laterally to the axis it can cause a number of problems. Avoid mounting with side loads on the stem, because the cylinders are specifically designed to go “back and forth” as efficiently. Pneumatic Cylinder Jerking Problem.

From www.pneumatictips.com

Why do pneumatic cylinders fail? Pneumatic Cylinder Jerking Problem at royal cylinders, our engineers provide troubleshooting support and solutions to industrial cylinder leakage, jerking, creeping, bouncing, chattering,. Avoid mounting with side loads on the stem, because the cylinders are specifically designed to go “back and forth” as efficiently as possible and not to act as guides. prevent pneumatic cylinder failure by maintaining and repairing it regularly. . Pneumatic Cylinder Jerking Problem.

From www.youtube.com

Pneumatic Double Acting Cylinder YouTube Pneumatic Cylinder Jerking Problem prevent pneumatic cylinder failure by maintaining and repairing it regularly. Our guide to pneumatic cylinder maintenance covers. the 4 conditions that can cause the pneumatic cylinder to fail are: if your pneumatic cylinder is failing, the most likely culprit is side loading. at royal cylinders, our engineers provide troubleshooting support and solutions to industrial cylinder leakage,. Pneumatic Cylinder Jerking Problem.

From enginedatacoaters.z21.web.core.windows.net

Pneumatic Circuit Diagram For Single Acting Cylinder Pneumatic Cylinder Jerking Problem Avoid mounting with side loads on the stem, because the cylinders are specifically designed to go “back and forth” as efficiently as possible and not to act as guides. prevent pneumatic cylinder failure by maintaining and repairing it regularly. Ideally there should be zero lateral loads on the cylinder. When pressure is applied laterally to the axis it can. Pneumatic Cylinder Jerking Problem.

From www.iqsdirectory.com

Pneumatic Cylinder What Is It? How Does It Work? Types Of Pneumatic Cylinder Jerking Problem the 4 conditions that can cause the pneumatic cylinder to fail are: if your pneumatic cylinder is failing, the most likely culprit is side loading. Avoid mounting with side loads on the stem, because the cylinders are specifically designed to go “back and forth” as efficiently as possible and not to act as guides. When pressure is applied. Pneumatic Cylinder Jerking Problem.

From www.youtube.com

Cylinder Calculation Hydraulic Cylinder Calculation Pneumatic Pneumatic Cylinder Jerking Problem Our guide to pneumatic cylinder maintenance covers. Avoid mounting with side loads on the stem, because the cylinders are specifically designed to go “back and forth” as efficiently as possible and not to act as guides. at royal cylinders, our engineers provide troubleshooting support and solutions to industrial cylinder leakage, jerking, creeping, bouncing, chattering,. if your pneumatic cylinder. Pneumatic Cylinder Jerking Problem.

From www.researchgate.net

Pneumatic circuit using singleacting cylinder (Cl 11). Simulation Pneumatic Cylinder Jerking Problem if your pneumatic cylinder is failing, the most likely culprit is side loading. Our guide to pneumatic cylinder maintenance covers. Ideally there should be zero lateral loads on the cylinder. prevent pneumatic cylinder failure by maintaining and repairing it regularly. the 4 conditions that can cause the pneumatic cylinder to fail are: Avoid mounting with side loads. Pneumatic Cylinder Jerking Problem.